What is

PVC membrane structure fabric?

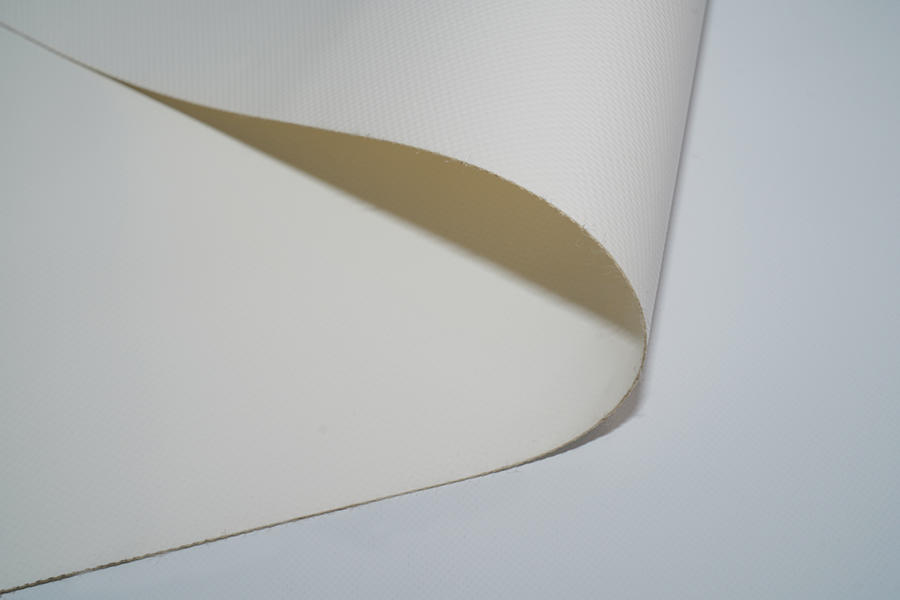

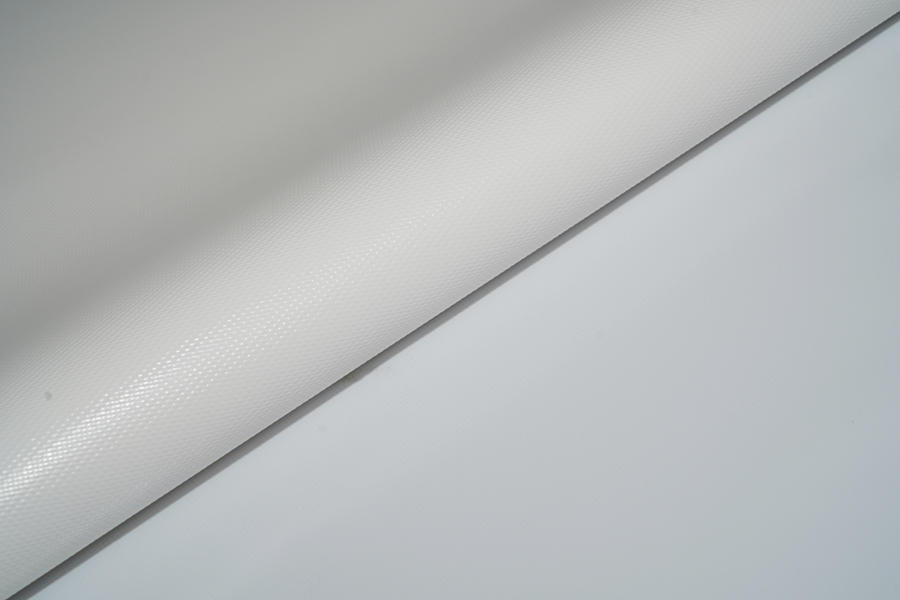

PVC membrane structure is generally a membrane project composed of PVC membrane structure fabric. PVC membrane structure fabric is the membrane structure material used by general membrane structure companies. PVC membrane structure fabric is made of polyester fiber and PVC membrane structure fabric coating. It is Several layers of acrylic resin (acrylic) of PVC membrane structure fabric are coated on the surface treatment of PVC membrane structure fabric coating material to improve the antifouling property of PVC membrane structure fabric, prolong the service life of PVC membrane structure fabric, and improve The fire performance of PVC membrane structure fabric, and the strength of PVC membrane structure fabric.

Compared with PTFE, the fire resistance of PVC membrane structure fabric is worse, its service life is 8~12 years, the fire resistance grade reaches the German secondary standard, and the strength of

PVC membrane structure fabric is 800n/5cm-4000n/5cm. The PVC membrane structure material is coated with titanium dioxide, and the PVC membrane structure fabric has a high self-cleaning property.

What will be involved in the construction of the PVC membrane structure fabric carport?

For the PVC membrane structure fabric parking shed engineering building, it is a building with a relatively strong sense of space, but the membrane material in its natural state is weak in compression, bending, and shearing, which makes the natural The

PVC membrane structure fabric in the state does not have a definite shape and the ability to accept loads. Only after a certain prestressed shape is applied to the membrane can it form a curved surface shape in a living space and make the structure form a certain rigidity and stability. For this kind of As far as the current situation is concerned, what analysis content related to manufacturing should we pay attention to in terms of its construction and manufacturing?

1. Morphological analysis

The so-called shape analysis is the analysis process of seeking the ideal geometric shape and reasonable initial stress state that meet the functional requirements of the building. The ideal geometric shape is the "shape" of PVC membrane structure fabric. The reasonable initial stress state is corresponding to the ideal structural shape. The process of "state" is a messy mechanical equilibrium problem. Now many scholars have devoted themselves to the research in this area, and have achieved certain scientific research results. At present, the commonly used methods are dynamic relaxation method, force density method, and nonlinear finite element method. .

2. Static analysis.

The loads of

PVC membrane structure fabric in static analysis are mainly snow load, wind load and membrane material self-weight. Under the effect of load, the structure is easy to appear wrinkled. There may also be accumulation of rain and snow in the low-lying places of the folds. It may even cause partial damage to the membrane material, thereby affecting the normal operation of the structure. Therefore, knowing more about the characteristics of wrinkles makes it a meaningful task to prevent the appearance of wrinkles as much as possible in practical engineering.

3. Power analysis

The dynamic analysis of PVC membrane structure fabric mainly considers the dynamic response of the structure under the effect of wind load. As a flexible structure, the response of PVC membrane structure fabric to wind load is very clear, and it will present very chaotic nonlinear vibration. Research in this area is still in the exploratory stage.

4. Cutting analysis

The PVC membrane structure fabric obtained by morphological analysis is generally a non-developable, segmented, lubricated and continuous curved surface. In actual engineering, it is necessary to cut and splice flat membrane materials to obtain the cutting analysis results, which will directly affect the structure in actual engineering. The degree of approximation to theoretical analysis results and the accuracy of load analysis.

6 advantages of

PVC membrane structure fabricPVC membrane structure fabric is a special structural system different from the traditional structure. The membrane is not only a structural load-bearing component, but also a roof enclosure material. At the same time, the membrane itself is a very good decorative material. Therefore, compared with the traditional structure, PVC Membrane structure fabric has the following advantages:

1. Department of Art. Based on modeling and color science, PVC membrane structure fabric can combine natural conditions and national customs, and build curves and shapes that are difficult to achieve in traditional buildings according to architects' creativity. The changeable support structure and flexible membrane material make the shape of the building more diverse, novel and beautiful, and at the same time reflect the beauty of the structure, and the colors are rich, which can create a more free architectural shape and express a richer architectural language.

2. Economy. The weight of the roof of the membrane building is only 1/30 of that of the conventional steel roof, which reduces the cost of the wall and foundation. At the same time, the unique shape and night scene effect of the membrane building have obvious "architectural recognizability" and commercial effects, and its price-benefit ratio is higher.

3. Energy saving. The film has high reflectivity and low light absorption, and low thermal conductivity, which greatly prevents solar energy from entering the room. In addition, because the film itself has good light transmittance (10%~20%), the translucency of the film ensures proper natural and slow scattered light to illuminate the room. Building space can get natural diffuse daylight during the day, which can save a lot of energy used for lighting.

4. Self-cleaning. The protective coating on the surface of the membrane, such as PVDF (polyvinylidene fluoride), has specific characteristics of high temperature resistance, and it is not sticky, so that the dust falling on the surface of the membrane can be self-cleaning by the natural washing of rainwater. .

5. Large-span unobstructed visual space. The weight of the membrane material used in PVC membrane structure fabric is only 1/30 of the traditional building material. Due to its light weight, the membrane building can not need the internal support surface to cover the space with a large span, which allows people to design more flexibly and creatively. and use of architectural space. Moreover, since the cable PVC membrane structure fabric provides rigidity through prestressing, the high tensile strength of the membrane material and the application of high-strength cables should realize a free and flexible large-span space structure, so it is especially suitable for covering stadiums and public facilities and other applications.

6. Shorter construction period. All processing and production in the PVC membrane structure fabric project can be completed in the factory according to the design, and only installation work is performed on site. Compared with the construction period of traditional buildings, it has incomparable advantages.