What is

PVC ventilation duct fabric?

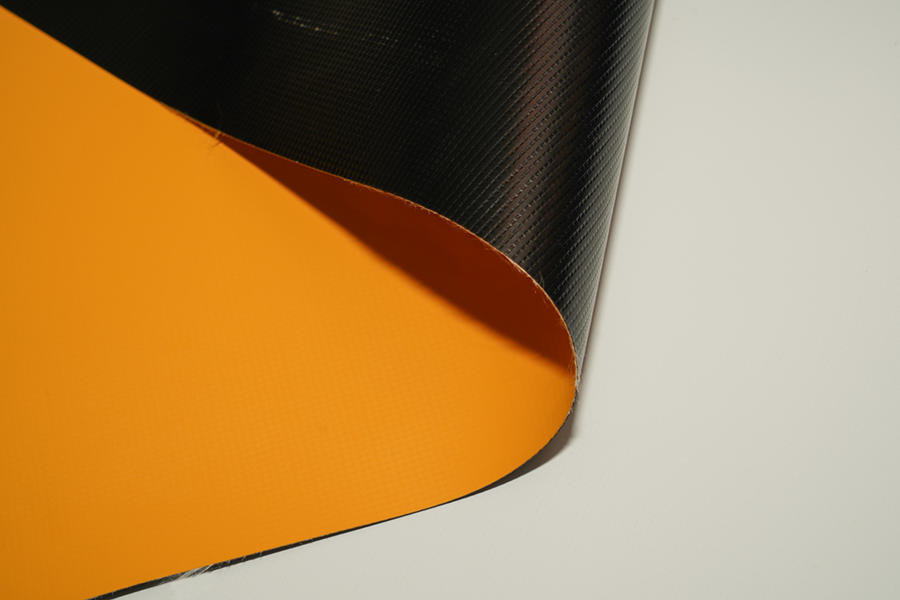

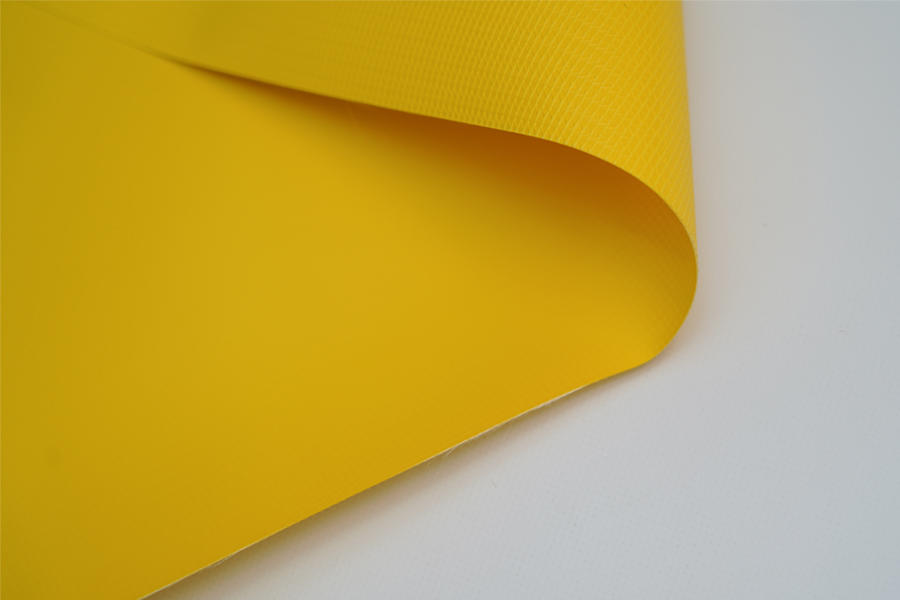

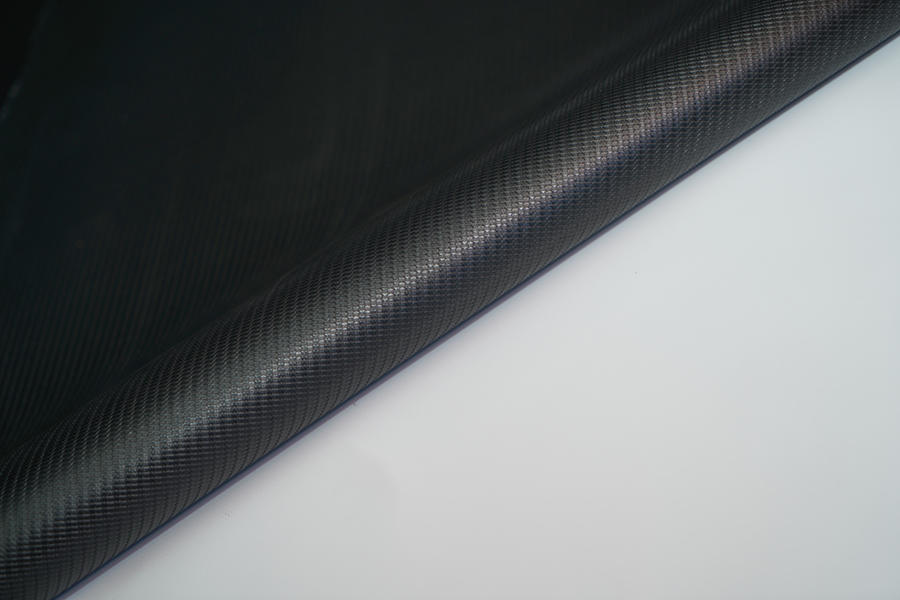

PVC ventilation duct fabric is made of polyvinyl chloride resin mixed with stabilizers, plasticizers, lubricants and other auxiliary agents, and then extruded by hot pressing.

In the fresh air industry, PVC ventilation duct fabric has a fatal weakness, that is, construction is inconvenient and not environmentally friendly, because PVC has no toughness and cannot meet the requirements of small bending, so many 45° or 90° elbows are needed in construction. It is time-consuming and labor-intensive, and glue needs to be used where the pipes are connected, and the glue contains a large amount of harmful substances such as formaldehyde and ethyl benzene. It is not recommended to use PVC ventilation duct fabric for all fresh air systems. HDPE pipes are recommended. The material itself is environmentally friendly food-grade PE. And the construction is flexible.

Is

PVC ventilation duct fabric the best piping material?

The suitability of PVC ventilation duct fabric as the best piping material depends on the specific application and requirements. PVC is a versatile and cost-effective material with many advantages, including:

Durability: PVC is impact, moisture and UV resistant, making it an ideal material for outdoor applications.

Chemical Resistance: PVC is resistant to many chemicals and acids, making it ideal for industrial applications where aggressive substances are present.

Lightweight: PVC is lighter than many other plumbing materials, making it easier to transport and install.

EASY TO INSTALL: PVC piping and piping can be easily cut, glued and fitted together, making installation quick and easy.

However, PVC also has some limitations to consider, such as its resistance to low temperatures, sensitivity to high temperatures and UV rays, and potential for stress cracking over time.

In conclusion, whether

PVC ventilation duct fabric is the best piping material depends on the specific requirements and constraints of the application. Before making a decision, it is important to consider all relevant factors, including operating conditions, system design and long-term performance.

Selection principles of PVC ventilation duct fabric

Many PVC ventilation duct fabrics on the market now involve impurities, and the mixture of various brands makes it difficult for consumers to choose. If you have a comprehensive understanding of Wuhan PVC ventilation duct fabrics, pay attention to safety and environmental protection, and don't be greedy for stinginess, which will cause a big loss. Improper selection of hoses in the project will directly lead to shortened life of the hoses, especially the hoses used in chemical plants, which will lead to aging, leakage, and even explosion. The results are unimaginable.

Today, let's talk about the principles of purchasing PVC ventilation pipes. The selection principle of PVC ventilation pipe:

1. When users choose

PVC ventilation duct fabric, they should go to reputable distribution points to choose products and brands of large enterprises. After our preliminary investigation, the qualified rate of non-brand PVC-U pipes sold in small roadside distribution points is less than 20%.

2. The user chooses to first apply the macroscopic inspection of the appearance and size, such as whether the circumferential wall thickness is uniform and whether the wall thickness is thick enough, and more comparisons can be made.

3. The toughness of PVC ventilation duct fabric is a very critical indicator. After sawing the pipe with high toughness, try to fold it 180°. If it breaks as soon as it is folded, it means that the toughness is poor and the brittleness is high; The pipe that can only be broken has good strength and generally good toughness. The broken stubble can be observed (except for the saw stubble), the finer the stubble, the better the homogenization, strength and toughness of the pipe.

4. The test report of the pipe and the test report of its hygienic indicators should be obtained.

PVC ventilation duct fabric series products are suitable for industrial and various building air conditioning and ventilation engineering installations, widely used in food processing, machinery manufacturing, pharmaceutical products, electronics industry, shopping malls, cotton textiles, sports entertainment and cultural venues, hotels, guesthouses, supermarkets, office buildings , small villas, family housing, aerospace manufacturing and other fields.